Reducing the Operating Cost

Reducing Operating Costs: Strategies for Efficiency and Profitability

Introduction: Operating costs are a significant concern for businesses across industries, including manufacturing, retail, services, and construction. Reducing operating costs without compromising quality or performance is key to improving profitability and long-term sustainability. As businesses strive to stay competitive, managing and reducing operating costs becomes a critical part of overall financial strategy.

Operating costs encompass a wide range of expenses related to the day-to-day running of a business, including labor, materials, utilities, equipment maintenance, and overhead. By identifying areas of inefficiency and implementing cost-saving strategies, businesses can achieve significant improvements in their bottom line.

In this article, we will explore effective strategies for reducing operating costs and enhancing business profitability.

1. What Are Operating Costs?

Operating costs, also known as operational expenses (OpEx), refer to the expenses that a business incurs as part of its normal business operations. These costs include both fixed and variable costs that are essential for running the business on a daily basis. Examples of operating costs include:

- Labor Costs: Salaries, wages, benefits, and contractor fees for employees and workers.

- Utility Costs: Energy, water, telecommunications, and other essential services.

- Rent and Leasing: Payments for office, warehouse, or retail space.

- Raw Materials and Supplies: Costs of raw materials, inventory, and consumables used in production or service delivery.

- Maintenance and Repairs: Ongoing costs of maintaining equipment, machinery, and facilities.

- Insurance and Taxes: Premiums, corporate taxes, and other regulatory fees.

- Marketing and Advertising: Costs related to promoting products or services, including advertising, digital marketing, and public relations efforts.

Managing and reducing these operating costs without sacrificing quality, customer satisfaction, or employee morale is essential for maintaining healthy profit margins and competitive advantage.

2. Strategies to Reduce Operating Costs

There are several ways to reduce operating costs, ranging from process improvements and technology adoption to better financial management and employee optimization. Below are some of the most effective strategies businesses can use to cut down on operating expenses.

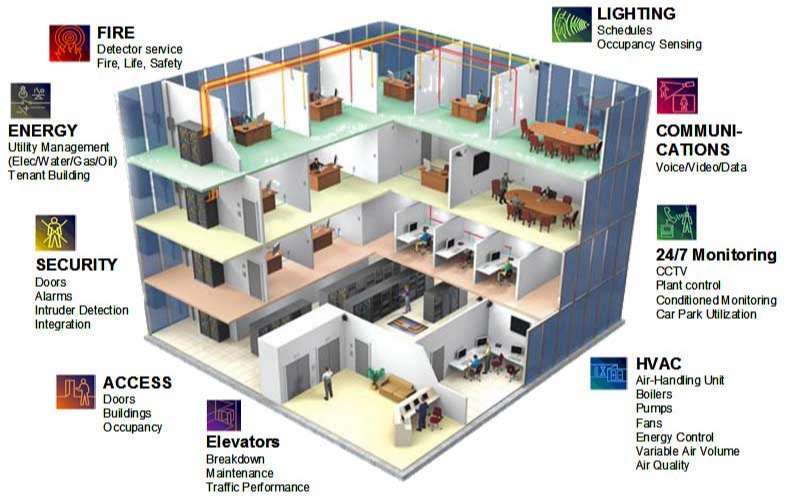

1. Optimize Energy Consumption

Energy costs are one of the largest operating expenses for many businesses, particularly those in manufacturing, hospitality, retail, and commercial real estate. Reducing energy consumption can have a significant impact on the bottom line.

- Upgrade to Energy-Efficient Equipment: Replacing outdated equipment with energy-efficient models (e.g., LED lighting, Energy Star-rated appliances, energy-efficient HVAC systems) can reduce energy use and lower utility bills.

- Implement Smart Energy Management Systems: Use smart thermostats, lighting control systems, and energy management software to optimize energy consumption based on real-time data and occupancy patterns.

- Energy Audits: Conduct regular energy audits to identify areas where energy is being wasted and implement energy-saving measures such as improving insulation or upgrading heating and cooling systems.

2. Automate Processes

Automation technologies can streamline business processes, improve productivity, and reduce labor costs. By automating repetitive tasks, businesses can free up employee time for more strategic activities while reducing the risk of human error and increasing operational efficiency.

- Automate Administrative Tasks: Use software tools to automate tasks like scheduling, payroll processing, invoicing, and inventory management.

- Robotic Process Automation (RPA): In industries like finance and customer service, RPA tools can handle data entry, claims processing, and customer queries more efficiently than manual labor.

- Manufacturing Automation: For manufacturers, the use of automated machinery and robotics can improve production efficiency, reduce material waste, and minimize the need for manual labor.

3. Outsource Non-Core Functions

Outsourcing is an effective way to reduce costs by shifting non-essential tasks to specialized service providers who can perform them more efficiently and at a lower cost. This allows businesses to focus on their core competencies while lowering operational expenses.

- Outsource IT Support: Instead of maintaining an in-house IT team, consider outsourcing IT services to managed service providers (MSPs) who can offer round-the-clock support at a fraction of the cost.

- Outsource Payroll and HR: Payroll processing, employee benefits administration, and recruitment can often be outsourced to third-party providers who offer specialized expertise at a lower cost.

- Logistics and Shipping: Outsourcing shipping and logistics to third-party providers can reduce overhead, eliminate the need for warehouses, and optimize transportation costs.

4. Optimize Workforce Management

Labor costs represent a significant portion of operating expenses for many businesses. By optimizing workforce management, businesses can reduce labor costs, improve productivity, and ensure efficient resource allocation.

- Flexible Staffing: Implement flexible staffing models, such as using temporary or part-time workers during peak periods, to avoid overstaffing during slow periods.

- Cross-Training Employees: Cross-training employees to perform multiple roles within the organization allows for greater flexibility and reduces the need for hiring additional staff.

- Telecommuting and Remote Work: Allowing employees to work from home or remotely can reduce office space requirements and associated costs like utilities, office supplies, and maintenance.

5. Review and Negotiate Supplier Contracts

Supplier costs can quickly add up, especially when businesses rely heavily on raw materials or third-party services. Reviewing supplier contracts and renegotiating terms can help reduce these expenses.

- Consolidate Purchases: Bulk purchasing or consolidating orders from fewer suppliers can help reduce material costs and potentially earn discounts or better pricing.

- Negotiate Better Terms: Regularly review and negotiate contracts with suppliers and service providers to ensure that you are getting the best possible rates. If applicable, switch to more cost-effective suppliers or consider alternative sources of materials.

- Leverage Technology for Procurement: Implementing procurement software can streamline the purchasing process, ensure competitive bidding, and optimize supplier selection.

6. Reduce Waste and Improve Efficiency

Reducing waste—whether in materials, time, or resources—can significantly lower operating costs. Lean principles, which focus on maximizing value while minimizing waste, can be applied across various business functions.

- Lean Manufacturing: In production environments, implementing lean manufacturing principles, such as reducing overproduction, improving inventory management, and eliminating bottlenecks, can lower costs and improve throughput.

- Waste Reduction in Office Operations: Implement practices like digital document management to reduce paper waste, or encourage employees to adopt energy-saving practices.

- Inventory Management: Improving inventory control can reduce storage costs, minimize waste from expired or obsolete stock, and prevent overordering, leading to more efficient operations.

7. Implement Cloud-Based Solutions

Cloud computing provides businesses with scalable and cost-effective alternatives to on-premises IT infrastructure, helping to reduce costs associated with hardware, software, and IT support.

- Cloud Storage and Backup: Moving data storage and backups to the cloud can eliminate the need for costly physical servers and storage devices.

- SaaS (Software as a Service): Many business applications, including accounting, customer relationship management (CRM), and project management tools, are available as cloud-based services with lower upfront costs and minimal maintenance fees.

- Collaboration Tools: Cloud-based collaboration tools like Google Workspace, Microsoft 365, and Slack can reduce the need for physical office space and improve communication and productivity.

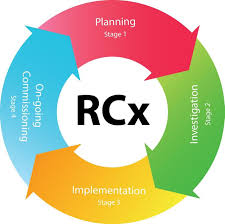

8. Implement Preventative Maintenance

Routine maintenance is essential for extending the lifespan of equipment, machinery, and facilities. Preventative maintenance helps identify and address potential issues before they become major problems, saving on repair costs and downtime.

- Scheduled Equipment Maintenance: Regularly scheduled inspections and maintenance of equipment, HVAC systems, and machinery can prevent costly breakdowns and extend the service life of assets.

- Facility Maintenance: Keep facilities in good condition by performing regular cleaning, inspecting safety systems, and maintaining electrical, plumbing, and HVAC systems to avoid unexpected repairs and disruptions.

9. Monitor and Manage Cash Flow

Effective cash flow management is a crucial aspect of reducing operating costs and maintaining financial stability. Poor cash flow can lead to unnecessary borrowing costs and missed opportunities for savings.

- Cash Flow Forecasting: Regularly monitor cash flow to ensure that the business has enough working capital to meet operating expenses and avoid financial strain.

- Delay Non-Essential Spending: Postpone or defer non-essential expenditures to prioritize essential investments and minimize unnecessary costs.

3. Benefits of Reducing Operating Costs

- Increased Profitability: By lowering operational expenses, businesses can increase their profit margins without increasing sales.

- Improved Cash Flow: Cost reduction strategies can free up cash, which can be reinvested into the business or used to pay down debt.

- Better Competitiveness: Reducing costs allows businesses to offer more competitive prices or invest in innovation and growth opportunities.

- Sustainability: Many cost-saving measures, such as reducing energy consumption or minimizing waste, also contribute to environmental sustainability, improving the company's corporate social responsibility (CSR) profile.

4. Conclusion

Reducing operating costs is a fundamental strategy for improving business profitability and efficiency. By adopting smart technologies, streamlining processes, renegotiating supplier contracts, optimizing workforce management, and implementing sustainability practices, businesses can lower their operational expenses without sacrificing performance. While cost reduction requires upfront investment and planning, the long-term benefits—such as improved cash flow, increased competitiveness, and greater profitability—make it a crucial aspect of business strategy in today's dynamic marketplace.